From the print edition

Making a mark

BP has laid solid foundations at the first phase development of Khazzan gas field. Exporting Khazzan’s first volume of gas marks the end of a 10-year journey. Muhammed Nafie reports

When BP achieved first gas at its Khazzan field on September 22, 2017, safely, ahead of schedule and below budget, it was one of the biggest BP start-ups anywhere in the world during the year.

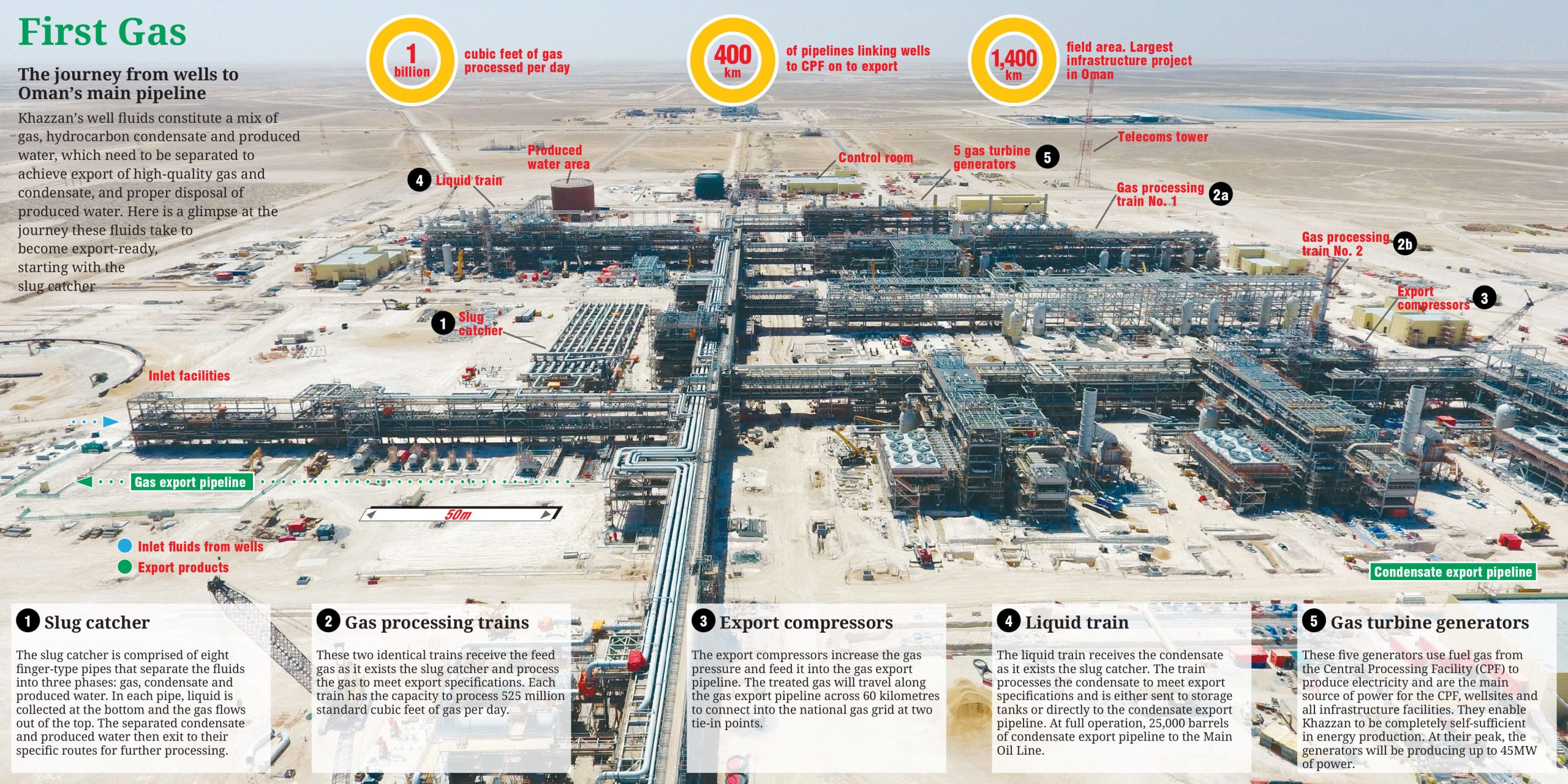

The phase one development started gas production ten years after the signing of BP’s production sharing contract with Oman and almost four years after the development was approved. Phase one will include a total of 200 wells feeding into a two-train Central Processing Facility (CPF), where production is expected to plateau at 1 billion cubic feet of gas per day (bcfd). When the second phase of development of the Khazzan field, known as Ghazeer, is fully on-stream total production is expected to rise to 1.5 (bcfd). In total, approximately 300 wells are expected to be drilled over the estimated lifetime of these two phases of development of the Khazzan field.

The most important stages of the huge project are horizontal and vertical wells. BP has drilled the wells across the field, laid hundreds of kilometres of pipelines and built a two-train Central Processing Facility (CPF). In addition, the company has put in place road, telecoms, water and power infrastructure and completed the construction of accommodation facilities.

The company is also able to run CPF at record time with high production. It already exports natural gas and condensate from train 1 and 2 and is looking to increase the production to one billion standard cubic feet of gas per day and 25,000 barrels per day of gas condensate.

Solid foundation

Exporting Khazzan’s first volume of gas marked not only the end of a 10-year long journey to build and set up the facility, but also BP’s commitment to operations in Oman for many more years to come. There was a clear focus on building the infrastructure to support operations – roads, camps, water and power which are vital for continued smooth progress. The ramp-up of rigs at the start of the well drilling programme was particularly demanding in this respect, but the company overcame these challenges successfully. The infrastructure BP has put in place should only need minor additions –to develop Ghazeer.

Says Mohsin Al Mahrouqi, Onshore Site Manager, Khazzan, “The operations of the giant Khazzan field are divided into three main sections: the operation of well sites and gathering systems; the central processing facility; and the export systems. The most important stages of this huge project were the drilling of the horizontal and vertical wells across the field and the construction, commissioning and startup of the Central Processing Facility (CPF). The fluid from the reservoir constitutes a mixture of gas, hydrocarbon condensate and produced water, which needs to be separated in order to achieve export quality gas and condensate, as well as proper disposal of produced water.”

Says Mohsin Al Mahrouqi, Onshore Site Manager, Khazzan, “The operations of the giant Khazzan field are divided into three main sections: the operation of well sites and gathering systems; the central processing facility; and the export systems. The most important stages of this huge project were the drilling of the horizontal and vertical wells across the field and the construction, commissioning and startup of the Central Processing Facility (CPF). The fluid from the reservoir constitutes a mixture of gas, hydrocarbon condensate and produced water, which needs to be separated in order to achieve export quality gas and condensate, as well as proper disposal of produced water.”

The fluid from the production wells is routed to the inlet of the plant (CPF) via a series of five gathering systems. At the inlet of the plant, the mixed fluid enters the finger type slug catcher where the mixed fluid is separated into three phases: gas, condensate and produced water. Gas flows at the top of the slug catcher and then enters two identical trains with a combined processing capacity of 1 billion standard cubic feet of gas per day for further processing. Here the gas undergoes various processes to remove impurities, water and heavy hydrocarbon in order to achieve export pipeline spec. Quality spec gas is then exported using 3 x gas turbine driven gas export compressors and connects in to the National gas network via a 36” gas export pipeline. The power is provided by five gas turbine generators located at the CPF.

Condensate from the bottom of the stabiliser is routed to the liquid train for stabilisation and then stored or exported to the Main Oil Line (MOL). The remaining product, water is sent to the produced water unit where it is treated for safe disposal to the water disposal wells.

The above operation is supported by associated infrastructure including a raw water treatment plant; sewage treatment plant; Khazzan operating base (KOB); the central control building (CCB) housing the central control room and two main residential complexes.

Human capital

With gas now flowing through its pipelines, making sure everyone at Khazzan can work together seamlessly is critical to success. A modern complex operation like Khazzan, needs a great deal more than just pipes and drilling rigs: it requires safety experts, geological scientists, procurement specialists, and an array of other talented staff. People are at the heart of everything BP does and so it’s no surprise that BP’s ‘one team’ value is lived by all staff working at Khazzan.

BP launched its Technicians training Development Programme in 2012. This was a great example of collaboration between the operations and learning team to support the development of capabilities ensure everyone was ready to operate the Khazzan field. Technicians were provided with development opportunities in alignment with the programme’s goals at various locations, including overseas (USA & UK). Closer to home we had different groups join Oman LNG and Oman Oil Company Exploration & Production (OOCEP) for a period of time. These opportunities provided 85 people with the appropriate technician skill sets, enabling them to commence work on the Khazzan Project.

The technicians, most of whom now have an NVQ3 qualification; as part of their Development Programme, joined Khazzan at a time when commissioning of the plant was in progress, providing them with the opportunity to get engaged in commissioning activities of the facility. This offered them a glimpse of how a well site, central processing facility and export systems are commissioned and started for the first time. On her experience working at the field, Husna Al Mamari, Production Technician says; “I have had a very enriching experience working at the field. It is not easy, but through my work and interacting with people, I have gained more experience, knowledge and self-confidence.”

The technicians, most of whom now have an NVQ3 qualification; as part of their Development Programme, joined Khazzan at a time when commissioning of the plant was in progress, providing them with the opportunity to get engaged in commissioning activities of the facility. This offered them a glimpse of how a well site, central processing facility and export systems are commissioned and started for the first time. On her experience working at the field, Husna Al Mamari, Production Technician says; “I have had a very enriching experience working at the field. It is not easy, but through my work and interacting with people, I have gained more experience, knowledge and self-confidence.”

Ensuring everyone’s safety and understanding of BP’s safety standards was paramount, particularly given that so many people from varying companies and countries were working together with differing understandings towards safety practices. The issue of synchronising various stages of the workflow – construction, mechanical completion, commissioning and start-up – required close attention to ensure safety was maintained and effectiveness maximised.

With Phase 2 of the development due to commence in early 2018, much of what has been learned and delivered to date will be vital for continued smooth progress.

-

Banking & Finance2 months ago

Banking & Finance2 months agoOman Oil Marketing Company Concludes Its Annual Health, Safety, Environment, and Quality Week, Reaffirming People and Safety as a Top Priority

-

News2 months ago

News2 months agoJamal Ahmed Al Harthy Honoured as ‘Pioneer in Youth Empowerment through Education and Sport’ at CSR Summit & Awards 2025

-

OER Magazines2 months ago

OER Magazines2 months agoOER, December 2025

-

News2 months ago

News2 months agoAI Security Conference 2025 Hosted by Securado Highlights the Changing Cybersecurity Landscape

-

Insurance1 month ago

Insurance1 month agoSupporting Community Wellness: Liva Insurance Sponsors Muscat Marathon 2026 with Free Health Checkups

-

Interviews1 month ago

Interviews1 month agoEXCLUSIVE INTERVIEW: TLS Rebranding Marks Strategic Leap Toward Innovation, Sustainability & Growth

-

Insurance4 weeks ago

Insurance4 weeks agoLiva Insurance Supports Community Wellness Through “Experience Oman – Muscat Marathon 2026”

-

Banking & Finance4 weeks ago

Banking & Finance4 weeks agoA New Platform for SME Growth: Oman Arab Bank Unveils Tumouhi

You must be logged in to post a comment Login